Restoration by Heroes Motors

Classic Cars and Motorcycles specialists

----------------------

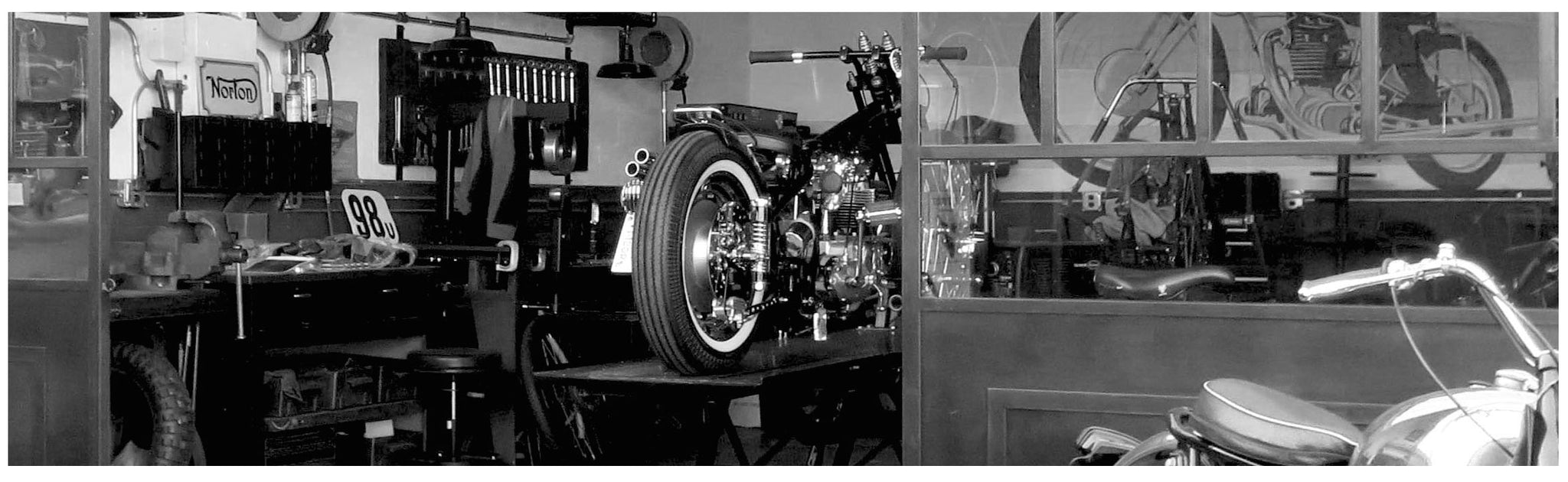

Known internationally for award-winning Concours restorations, Heroes Motors Los Angeles offers clients a world-class experience in the restoration and preservation of their vehicles With 100% of work completed within our 5,000 sq. ft. facilities.

Heroes Motors has unparalleled in-house capabilities that allows us to provide not only complete Concours restorations but maintenance and specialty services for a distinctive client experience.

One of the most satisfying jobs during a restoration project is to bring the engine, or the whole motorcycle, back to its original glory.

Serge Bueno, the founder of Heroes Motors, oversees all projects personally, being involved from start to finish, as he did many times on the restorations of his own bikes for the past 20 years.

But it usually starts with a few conversations where we try to understand how you see the transformation of your 'pride and joy'.

Serge Bueno will suggest ideas and ways to undertake the work by focusing on either creative design or improvement at the right cost.

For more details or to schedule an appointment,

1926 AMILCAR CGSS

1929 MAJESTIC MOTORCYLE

1930 MAJESTIC SIDE-CAR

1948 MG TC

CUSTOM MOTORCYCLE

10 Phases of Restoration

Phase 1 - Intake

During the intake process we invite you to visit our facilities to meet our team members before sitting down together to review the vehicle goals and objectives. If you are unable to meet on-site it is no problem to make arrangements via conference call or video conferencing. We take the necessary time to fully understand the entire scope of the project by identifying all the needs of the vehicle and balancing that with your requests as a client. Through this initial step we identify challenges, set preliminary scheduling for major project milestones, complete the pre-disassembly, photograph the vehicle, begin any research, and identify trim fitment issues in order to acquire materials for the disassembly and body 1 phase.

Phase 2 - Disassembly

This step includes the removal and evaluation of all vehicle components, fasteners and parts to identify correct and incorrect items. Within this phase we also delegate all internal accountabilities and draft part and material orders.

Phase 3 - Components

Any part which is more complex than a standard fastener is considered a component. All components are reconditioned in-house and bench tested prior to reassembly. This process begins after disassembly and is carried out until the assembly phase begins.

Phase 4 - Paint 1

Paint 1 is our paint removal process which is based on project requirements and can include chemical, mechanical and blasted media processes.

Phase 5 - Metal fabrication

This is our first milestones and important decisions are made with you at this time. At this point we invite you to visit our facility and see your vehicle in its raw form. We use this phase to outline repairs to be performed.

Within this stage we execute corrosion repairs, panel form corrections as well as fit doors, lids, glass and trim. The suspension can also be fitted with the wheels and tires to verify clearances as required.

This stage helps to determine the overall projected cost of the project.

Phase 6 - Trim

In order to expedite our processes more efficiently we perform the metal fabrication and trim phases simultaneously. All notations made during the intake phase are applied to pre-fitted trim components and any adjustments or repairs are completed.

Phase 7 - Paint 2

This is our second milestone involving the paint color selection.

This phase involves the painting of the inner body, exterior body and chassis. Prior to the color application there is a number of “pre” paint steps that are performed to ensure our quality standards are being met. First, we start with corrosion prevention of bare metal surfaces, next is an epoxy coating prior to any filler work, seems are welded, and repairs treated to prevent flaws in the final color coat. All repaired and rough fit trim is placed for a final fitting prior to color application. Finally, a color coat application is applied to primary polish.

Phase 8 - Assembly

The assembly process is where the fruits of our team’s efforts begin to show. As it implies, this is the phase where all the existing, repaired and new parts of the vehicle are put back together. In addition to the assembly, initial discussions of the upholstery work can begin in this phase.

Phase 9 - Upholstery

This is the third milestone. Early on in the assembly phase we will begin talking about finalizing leather selections. You will be invited back to the shop to see the progress first-hand as well as to select the upholstery colors to coordinate with the painted car.

Phase 10 - Release

This is when the fun begins. We are allowed the opportunity to re-introduce you to your vehicle at the venue of your choosing. Many of our projects are debuted at major concours events across the nation. If rejoining your collection is its final destination, logistical arrangements can be made and carried out by our team. We provide a flash drive with all relevant photographs and documents of your project as well as a binder crafted as a gift from our team to yours.